Viscosity plays an important role in filtration because it impacts the speed at which the fluid can be pushed through a filter to remove contaminants.Īt COMO Filtration we take many different factors into consideration when making a recommendation for you. Selecting a filter with a larger micron size will help decrease the pressure drop since there will be less resistance moving through the filter. This is because higher viscosity fluids have a higher resistance to flow resulting in a higher pressure drop and shorter filter life. As fluid viscosity increases, the flow rate that is pumped through a filter must be decreased. Viscosity plays an important role in filtration because it impacts the speed at which the fluid can be pushed through a filter to remove contaminants. For example, if a hydraulic oil with a kinematic viscosity of 68 cSt 40☌ (104☏) is measured for viscosity and is 75 cSt (104☏) it would be considered out of spec and should be replaced. Typically a fluid that is +/- 10% of its original viscosity would be considered out of spec and should be replaced. Monitoring the oil viscosity is also important because it can tell you if the fluid itself is within spec. If the viscosity becomes too high it can result in oil oxidation, varnish build-up, and poor pumpability throughout your machine. When the viscosity is too low it can result in a loss of oil film which will lead to excessive wear and increased mechanical friction. If the fluid viscosity falls outside of the recommended range for machine components it can no longer provide adequate lubrication to keep components protected. When it comes to machine guidelines, fluid viscosity is one of the most critical aspects to monitor. This is because viscosity will increase with higher temperatures and decrease with lower temperatures. Both cSt and SUS specifications are given at two temperatures, 40☌/100☌, or 100☏/212☏ respectively. Centistokes (cSt) and Saybolt Universal Seconds (SUS) are the two main units of measurement used when referencing kinematic viscosity. When looking at the viscosity specifications of a fluid we are typically looking at the kinematic viscosity. There are two main kinds of viscosities when dealing with fluid: Dynamic viscosity, which is a measure of internal resistance to force, and Kinematic viscosity, which is a measure of internal resistance to flow when no force other than gravity is applied.

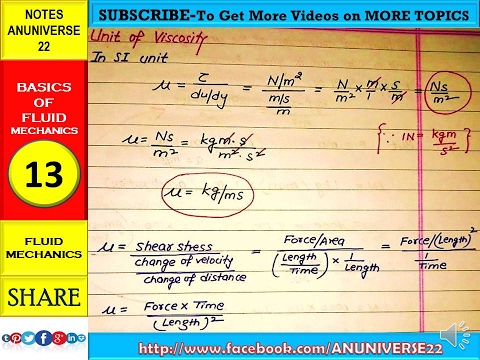

The viscosity of crude oils can be measured using a standard method (ASTM D2983).The technical definition of viscosity when it relates to fluid is “a measure of its resistance to deformation at a given rate.” However, different reference temperatures, such as 40☌ (104 ☏), 50 ☌ (122 ☏), and 60 ☌(140 ☏), are also used to report kinematic viscosities of petroleum fractions. Values of kinematic viscosity for pure liquid hydrocarbons are usually measured and reported at two reference temperatures, 38☌ (100☏) and 99☌ (210☏) in cSt. Kinematic viscosity is expressed in units of centistokes (cSt), Saybolt Universal seconds (SUS), and Saybolt Furol seconds (SFS). Viscosity of liquids is usually measured in terms of kinematic viscosity, which is defined as the ratio of absolute (dynamic) viscosity to absolute density (ν = μ/ρ). Among petroleum products, viscosity constitutes a critically important characteristic of lubricating engine oils. Interestingly, the viscosity of liquid decreases with increasing temperature, while viscosity of gases increases with increasing temperature. Power requirement to transport (e.g., to pump) a fluid depends strongly on the fluid’s viscosity. Newton’s Law of Viscosity provides a physical definition of viscosity. A high-viscosity fluid has a low tendency to flow, whereas low-viscosity fluids flow easily. Viscosity, commonly depicted by the symbol μ, is a physical property of a fluid that describes its tendency/resistance to flow.

0 kommentar(er)

0 kommentar(er)